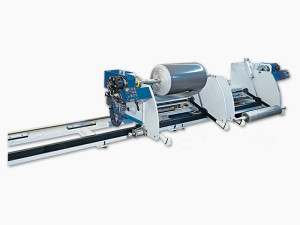

Descrizione prodotto

It is equipped with AUTOMATIC TURRET ROTATION – AUTOMATIC TRANSVERSAL CUT-OFF WITH AUTOMATIC RE-STARTING – UNLOADING SYSTEM OF THE FINISHED ROLLS .

All this allows to drastically reduce the downtimes between one cycle and another as well as a considerable production increase.

MAIN FEATURES:

- Working width: up to 2300 mm.

- Min. slitting width: 20 mm.

- Finished logs max. diameter: 600 mm.

- Minimum gap and Lay-on rollers

- Finished logs inside diameter: 3” (6″ and 10″ upon request)

- Slitting systems: razor-blades, score-knives and shear-knives – traditional type or with automatic positioning.

- Mechanical speed: from 450 up to 650 m./min. according to the machine configuration

- Trims group: vacuum or rewound type

- Rewinding shafts: pneumatic-differential, differential, pneumatic type.

FITTINGS:

- AUTOMATIC UNLAODING SYSTEM OF THE FINISHED ROLLS

- Splicing table

- Automatic application of adhesive or double-adhesive end-tabs for logs closing.

- Material inspection table

- Liner recovery station

- Scrap winder

- Finished rolls conveyance to packaging station

OTHERS FITTINGS AND DEVICES ACCORDING TO THE MATERIALS

AND THE NEEDS OF THE CUSTOMER