Descrizione prodotto

BA 90 with the Automatic spools Loader mod. CFL110 and with the cores Loader mod. CL500/SP creates a flexible and performing production line able to produce any type of medical tapes on plastic spools and cardboard cores.

MAIN FEATURES

- Working width: up to 1650 mm.

- Finished rolls width: from 1 cm. to over 10 cm.

- Driven unwinding

- Finished rolls max. diameter:

– 55 mm. on spools

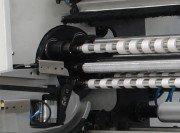

– 80 mm. on carton cores - Rewinding group with 10 rewinding shafts – pneumatic expanding type

- Rollers of Slitter-Rewinder and Unwinder treated with Plasma Coating

- Longitudinal slitting system: score-knives, standard or zig-zag type

- Automatic end cut-off

- Automatic transfer system of the rewinding shafts from the Slitter-Rewinder to the Core Loader and vice versa.

- Time needed for the size changeover: 15 min. approx.

PRODUCTION

- Cycle time for 5 m. rolls: 2 CYCLES PER MINUTE

FITTINGS

- Delaminating, Slitting, Laminating system of the Liner with double adhesive end-tabbing group (for rolls with split liner)

- Liner recovery station

- End-tab for rolls of NO-WOVEN

- Splicing table

- Stainless steel casing

- Belts and conveyor systems to packaging lines

NOTE

To limit the investment and the spaces it is possible to equip the BA90 with a semi-automatic Loader mod. CAP that allows the loading-unloading of the medical tapes both on SPOOLS and CARDBOARD CORES.

OTHERS FITTINGS AND DEVICES ACCORDING TO THE MATERIALS

AND THE NEEDS OF THE CUSTOMER